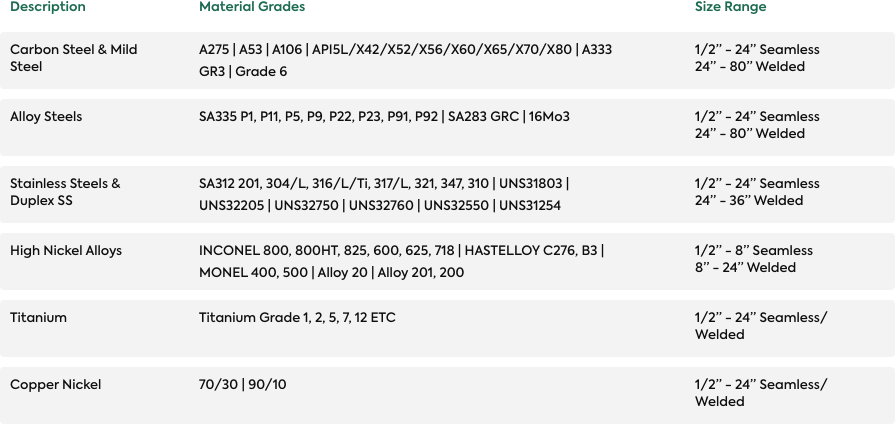

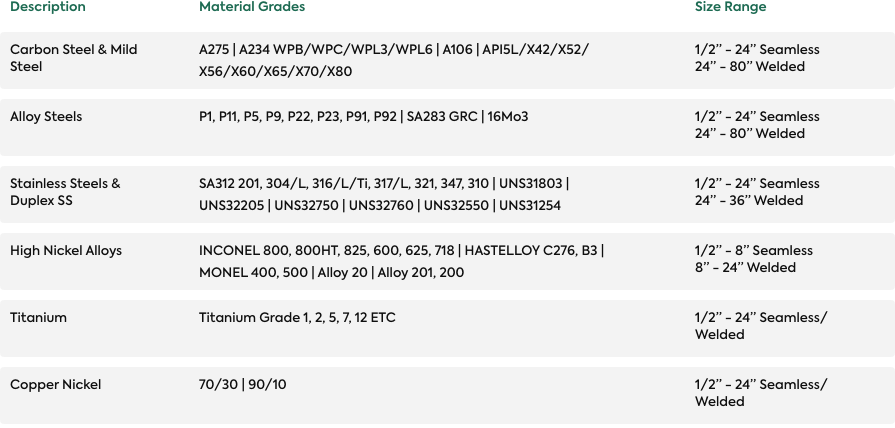

Forms

Alloy 2120 Applications

Alloy 2120 MoN is a nickel-chromium-molybdenum alloy with particularly low carbon content and an addition of

nitrogen. The material distinguishes itself through an outstanding corrosion resistance under

reducing as well as under oxidizing conditions. Furthermore, Alloy 2120 MoN is characterized by superior strength

compared to other C alloys.

Alloy 2120 MoN is characterized by:

- Extraordinary resistance against pitting and crevice corrosion as well as against chlorine induced stress corrosion

cracking. - Excellent resistance against a huge number of corrosive media, beginning with strong reducing conditions right

up to oxidizing conditions. - Excellent resistance against mineral acids like sulfuric acid, hydrochloric acid.

- Good ductility.

- Good weldability.

- Intended application area of -196 to 450 °C (-320 to 842 °F).

- Approval for pressure vessels according to ASME Code Section VIII Div 1; Section VIII Div 2, Class 1 applications

Alloy 2120 MoN has a wide range of applications in the chemical, petrochemical and pharmaceutical industries as

well as in energy production and environmental technologies.

Typical applications include:

- Components in flue gas desulfurization and waste incineration plants as e.g. scrubbers, raw gas inlets and heat

recovery systems. - handling of mineral acids like sulfuric acid, hydrochloric acid and acid mixtures even when contaminated with

chlorides - acetic acid and acetic anhydride production

- production and processing of halogen containing chemicals

- equipment for organic synthesizes and fine and specialty chemicals production

- components exposed to seawater and to highly concentrated brines

- sour gas and geothermal services

Alloy 2120 Plate Standards

| Rod,Bar | - | - | - | B 574 |

| Sheet,Plate | - | - | - | B 575 |

| Strip | - | - | - | B 575 |

| Tube and Pipe Welding | - | - | - | B 619 B 626 |

Alloy 2120 Designations

| EN | 2.4700 |

| UNS | N06058 |

Alloy 2120 Chemical Composition

| Min | - | 20.0 | 18.5 | - | - | - | - | - | - | - | 0.02 | - | - | - |

| Max | balance | 23.0 | 21.0 | 1.5 | 0.5 | 0.4 | 0.3 | 0.3 | 0.1 | 0.50 | 0.15 | 0.01 | 0.01 | 0.015 |

Alloy 2120 Physical Properties

| 8.6 g/cm3 (537 lb/ft3) | 1,330 - 1,370 ℃(2,426 - 2,498 ℉) | The material is non-magnetic |

| Specific Heat | 406/0.097 | 457/0.109 | 471/0.112 | 482/0.115 | 487/0.116 | 546/0.130 | |

| Thermal Conductivity | 9.8/5.66 | 13.0/7.51 | 15.5/8.67 | 16.9/9.76 | 18.5/10.7 | 21.8/12.6 | |

| Electrical Resistivity | 124 | 125 | 126 | 127 | 129 | 130 | |

| Modulus Of Elasticity | -/- | 194/28.1 | 188/27.3 | 182/26.4 | 177/25.7 | 169/24.5 | |

| Co-efficient of Thermal Expansion | 11.4/6.36 | 12.2/6.76 | 12.5/6.96 | 12.9/7.17 | 13.2/7.32 | 13.8/7.64 |

Alloy 2120 Mechanical Properties

| Yield Strength MPa/ksi |

360/52.2 | 200/29.1 | 180/26.1 |

| Tensile Strength MPa/ksi |

760/110 | 560/81.2 | 530/76.9 |

| Elongation % |

40 | 40 | 40 |

Welding Alloy 2120

Following filler metals are recommended

| The following filler material is recommended: Welding rods, welding wire and wire electrodes |

|---|

|