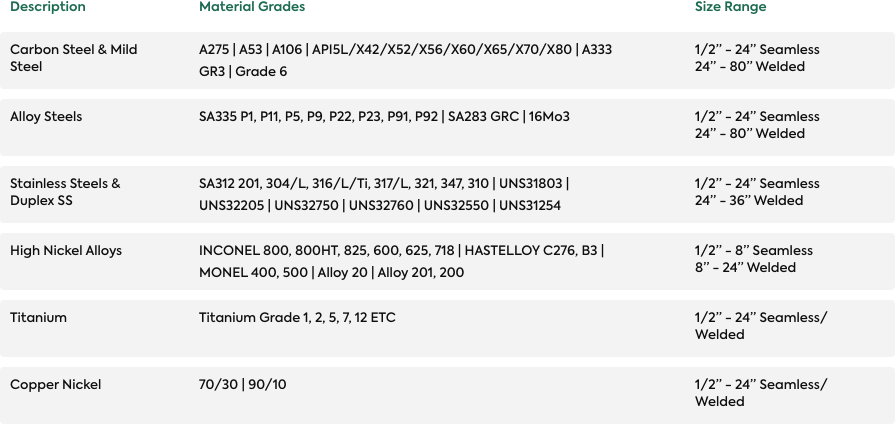

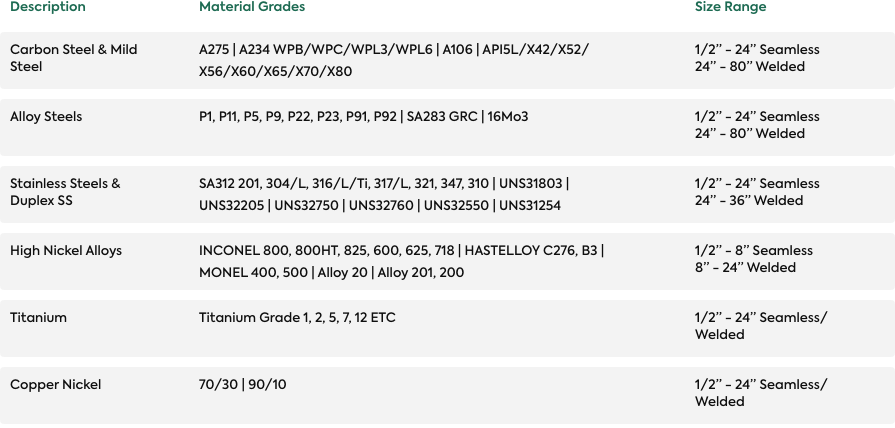

Forms

Alloy 276 Applications

Alloy C-276 has a broad field of application in the chemicals and petrochemicals industry, for components in

organic processes containing chlorides, and for catalytic systems. The material can be used especially in cases where

hot, contaminated mineral acids, solutions or organic acids (such as formic acid and acetic acid) and sea water occur.

Examples of fields of application:

- Paper and pulp industry, e.g. for digestion and bleaching tanks.

- Washers, agitators and wet ventilators in flue gas de-sulfurization systems.

- Equipment and components for acid gas applications.

- Reactors for acetic acid production.

- Sulphuric acid coolers.

- Methylene diphenyl isocyanate (MDI).

- Manufacturing and processing of contaminated phosphoric acid.

Alloy C-276 is a nickel-chrome-molybdenum alloy with tungsten. It is characterised by:

- Extraordinary resistance across a wide range of corrosive, watery media; in particular oxidising and reducing acids.

- Particularly high resistance against chloride-induced crevice, pitting and stress corrosion.

Alloy 276 Plate Standards

| Sheet,Plate | 17744 | B 575 | SB 575 |

| Strip | 17744 | B 575 | SB 575 |

| Rod,bar,forging | 17744 17752 |

B 574 B 564 |

SB 574 SB 564 |

| Wire | 17744 17753 |

- | - |

Alloy 276 Designations

| EN | 2.4819 - NiMo16Cr15W |

| ISO | NiMo16Cr15Fe6W4 |

| UNS | N10276 |

| AFNOR | NC17D |

Alloy 276 Chemical Composition

| Min | 51 | 15 | 4 | - | - | - | 3 | 15 | - | - | - | - |

| Max | 63 | 16.5 | 7 | 0.01 | 1 | 0.08 | 4.5 | 17 | 2.5 | 0.3 | 0.02 | 0.01 |

Alloy 276 Physical Properties

| 8.9 g/cm3 (0.32 lb/in3) | 1,325 - 1,370 ℃(2,417 - 2,498 ℉) | 1.001 (Maximum) |

| Specific Heat | 426/0.102 | 453/0.108 | 493/0.118 | 605/0.145 | 605/0.145 |

| Thermal Conductivity | 10.2/70.8 | 13.4/93.0 | 18.1/125.6 | 25.8/179.0 | 27.2/188.7 |

| Electrical Resistivity | 125 | 128.5 | 129 | 126.5 | 125.5 |

| Modulus Of Elasticity | 208/30.2 | 200/29.0 | 182/26.4 | 160/23.2 | 143/20.7 |

| Co-efficient of Thermal Expansion | 12.1/6.72 | 12.8/7.11 | 13.4/7.44 | 14.6/8.11 | 15.6/8.67 |

Alloy 276 Mechanical Properties

| Yield Strength MPa/ksi |

310/45.0 | 240/34.8 | 195/28.3 | 150/21.8 |

| Tensile Strength MPa/ksi |

700/101.5 | 630/91.4 | 570/82.7 | 530/76.9 |

Welding Alloy 276

Alloy C-276 can be welded using all of the common welding processes, such as GTAW (TIG), GTAW (TIG) hot

wire, plasma and GMAW (MIG/MAG).

| The following welding consumable is recommended |

|---|

|