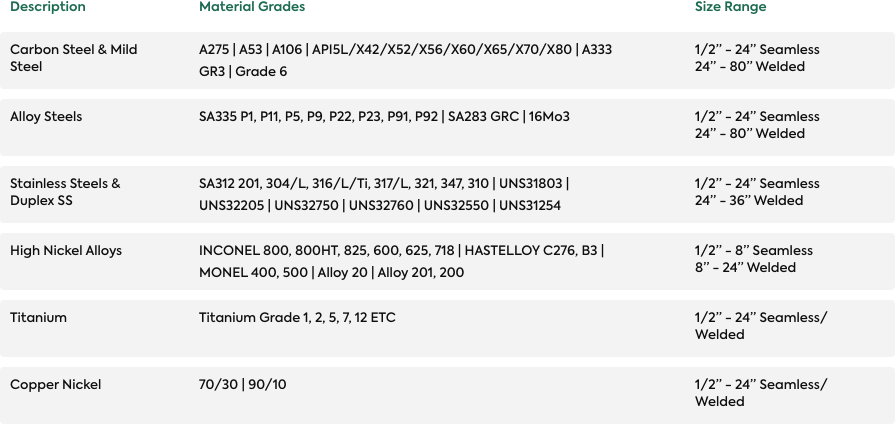

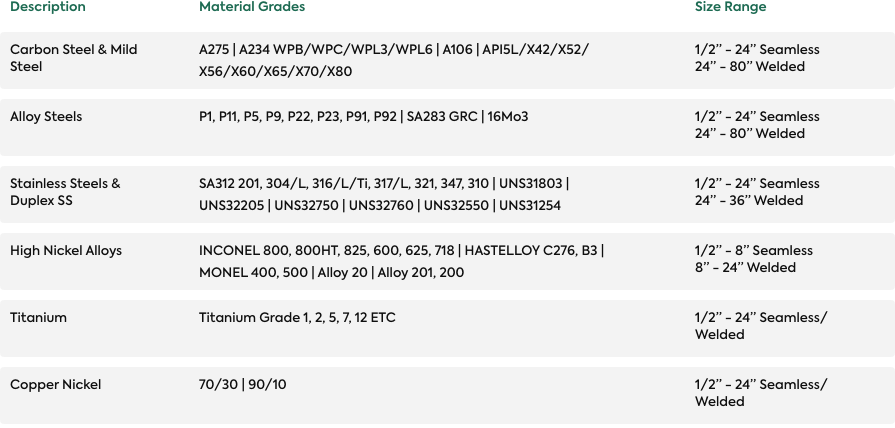

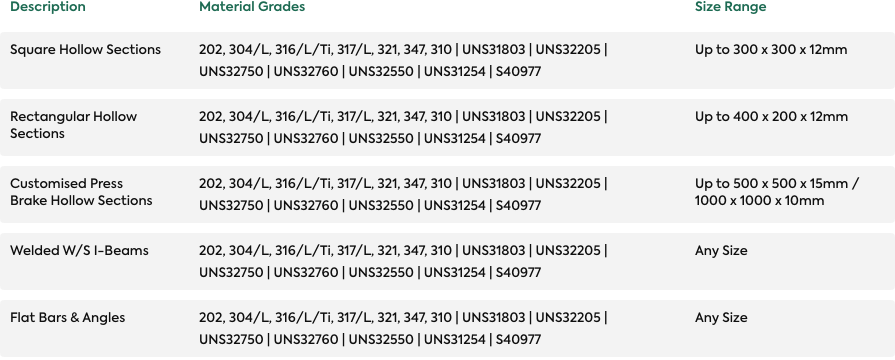

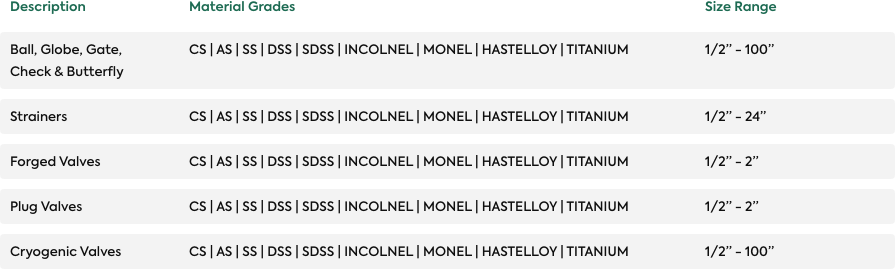

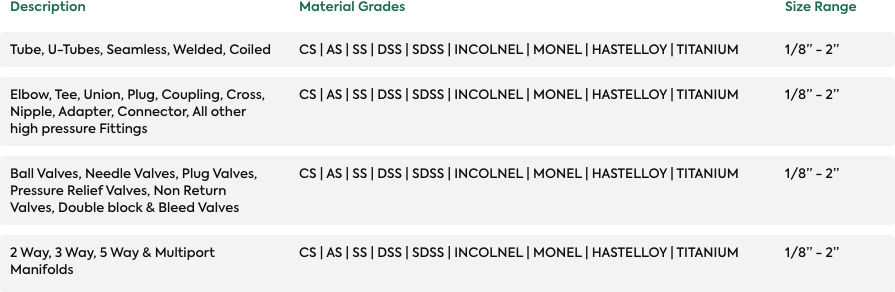

Forms

Alloy 31 Applications

Typical fields of application for Alloy 31 are:

- Components for flue gas desulfurization plants.

- Plants for the production of phosphoric acid via the wet digestion process.

- Pipes and heat exchangers for sulfuric acids contaminated with chlorides.

- Pipes containing ocean water and brackish water, condensers and chillers.

- Pickling plants for sulfuric acid as well as nitric-hydrofluoric acid.

- Treatment of sulfuric acids from waste.

- Evaporation and crystallization of salts.

- Components for the cellulose and paper industry.

- Digestion of ores, e.g. in HIPAL (high-pressure acid leach) plants for the digestion of laterite ores.

- Mineral oil production and refineries.

- Organic acids and ester synthesis.

- Fine chemicals.

- Strain-hardened transport and feed pipes as well as slicklines, wirelines and flowlines in the transport of oil and

gas.

Alloy 31 is an iron-nickel-chromium-molybdenum alloy with the addition of nitrogen. The alloy developed by VDM

Metals closes the gap between high alloyed austenitic special stainless steels and nickel alloys. Alloy 31 has

proven itself to be suitable particularly in the chemical and petrochemical industries, in ore digestion plants, in environmental and marine engineering as well as in oil and gas extraction.

Alloy 31 is characterized by:

- Outstanding corrosion resistance in alkaline and acidic halide-containing media.

- Excellent resistance to sulfuric acid, even in highly concentrated form.

- Excellent resistance to corrosion and erosion in phosphoric acid media.

- Outstanding resistance to surface corrosion and local corrosion in chlorine dioxide bleaching plants in paper

production. - Excellent resistance in reducing and oxidizing media as well as in boiling azeotropic nitric acid.

- Good workability and weldability.

- VdTÜV-certification for pressure vessels with operating temperatures from -196 to 550 °C (-320.8 to 1,022 °F).

- Certification according to ISO 15156/NACE MR 0175 up to level VI for acid gas applications in the oil and gas

industry. - ASME approval for pressure vessels up to 800 °F (427 °C).

Alloy 31 Plate Standards

| Rod,Bar | 509 | 400 | SB 581 SB 649 |

B 581 B 649 |

| Sheet,Plate | 509 | 400 | SB 625 | B 625 |

| Strip | 17744 | 2662 | SB 443 | B 443 |

| Wire | 509 | 400 | SB 649 | B 649 B 564 |

Alloy 31 Designations

| D | 1.4562 - X1NiCrMoCu32-28-7 |

| ISO | NACE MR0175/ISO 15156:2003 |

| UNS | N08031 |

Alloy 31 Chemical Composition

| Min | 30.0 | 26.0 | Balance | - | - | - | - | 6.0 | 1.0 | 0.15 | - |

| Max | 32.0 | 28.0 | Balance | 0.010 | 0.3 | 2.0 | 0.020 | 7.0 | 1.4 | 0.25 | 0.015 |

Alloy 31 Physical Properties

| 8.05 g/cm3 (0.29 lb/in3) at 20 ℃ (68 ℉) | 1,330 - 1,370 ℃(2,426 - 2,498 ℉) | 1.001 (Maximum) |

| Thermal Conductivity | 11.7/81.2 | 15/104.1 | 16.8/116.6 | 18.5/128.4 | 20.2/140.1 | 21.9/151.9 |

| Electrical Resistivity | 104 | 110 | 113 | 116 | 118 | 120 |

| Modulus Of Elasticity | 198/28.7 | 183/26.5 | 176/25.5 | 170/24.7 | 163/23.6 | 158/22.9 |

| Co-efficient of Thermal Expansion | -/- | 14.7/8.17 | 15.1/8.39 | 15.5/8.61 | 15.7/8.72 | 15.9/8.83 |

Alloy 31 Mechanical Properties

| Yield Strength MPa/ksi |

280/40.6 | 180/26.1 | 150/21.8 | 125/18.1 |

| Tensile Strength MPa/ksi |

650/94.3 | 580/84.1 | 500/72.5 | 450/65.3 |

| Elongation % |

40 | 40 | 40 | 40 |

Alloy 625 Inventory

| Alloy 625 Pipe | 0.5 in | 8 in |

| Alloy 625 Coil | 0.25 mm | 3.18 mm |

| Alloy 625 Welding Wire | 0.5 mm | 3.175 mm |

| Alloy 625 Sheet and Plate | 0.25 mm | 76.2 mm |

| Alloy 625 Round Bar | 12 mm | 260 mm |

| Alloy 625 Pipe Fittings | 0.5 in | 8 in |

| Alloy 625 Flanges | 0.5 in | 8 in |

Welding Alloy 31

Alloy 31 can be welded using conventional processes with metals of the same type as well as many other metals.

This includes GTAW (TIG), GMAW (MIG/MAG) and plasma welding. Pulsed arc welding is preferred for gas-shielded

welding processes. The use of a multi-component shielding gas (Ar + He + H2 + CO2) is recommended for the MAG

processes.

For welding, Alloy 31 should be in a solution-annealed condition and free of scale, grease and markings. When welding the root, care should be taken to achieve best quality root protection using pure argon (argon 4.6)

so that the welding edge is free of oxides after welding the root.

Root protection is also recommended for the first and, in

certain cases depending on the welded construction, also for the second intermediate layer weld after root welding.

Any tempering colors must be removed while the welding edge is still hot, preferably using a stainless steel brush.

The use of the following fillers is recommended for gas-shielded welding methods

| Welding rods and wire electrodes |

|---|

|

The use of coated electrodes is possible