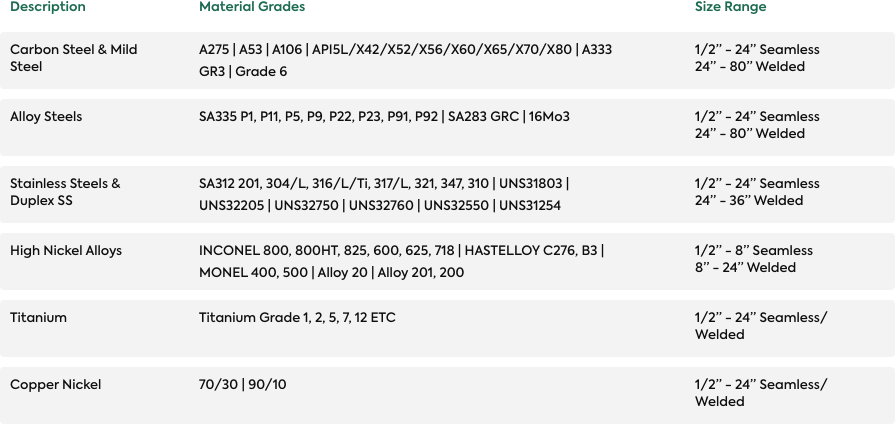

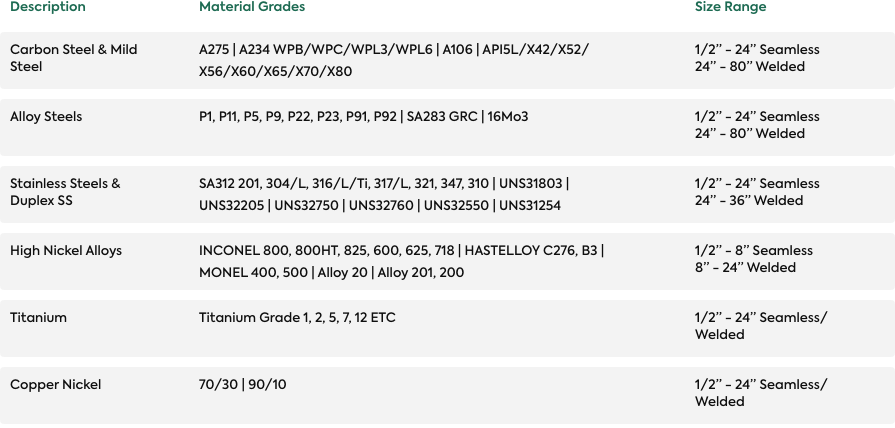

Forms

Alloy 600/600 H Applications

Typical applications for Alloy 600 and 600 H are:

- Transport rollers, steel pipes, ventilators and other installations in industrial furnaces.

- Industrial furnace muffles, in particular for heat treatment in N2 atmospheres.

- Thermal element protective conduits in nitriding and carburizing atmospheres.

- Pipes for dichloroethylene pyrolysis.

- Components in the production of uranium tetrafluoride from hydrofluoric acid.

- Production of caustic alkalis, especially with the presence of sulphur bonds.

- Reaction vessels and heat exchanger pipes in the production of vinyl chloride.

- Plant parts for the production of chlorinated and fluorinated hydrocarbons.

- Parts such as cladding tubes for control rods, reactor tanks and seals, steam dryers and separators in boiling

water reactors. - Pipes in TiCl4 evaporators in the production of TiO2.

- For the automotive industry the alloy is used for high temperature sensors, rupture discs in airbag systems,

electrodes for spark plugs and gaskets. - Vessels and piping used to contain caustic solutions.

Alloy 600 and the solution-annealed variant 600 H are nickel-chromium-iron alloys.

They are characterized by:

- Good resistance against oxidation, carbonization and nitriding

- Good resistance to stress corrosion in room and increased temperatures.

- Good resistance against dry chlorine and hydrogen chloride.

- Good mechanical properties at both low and high temperatures.

Alloy 600/600 H Plate Standards

| Rod,Bar | 17752 17742 |

10095 | B 166 564 |

SB 166 SB 564 |

| Sheet,Plate | 17750 17742 |

10095 | B 168 | SB 168 |

| Strip | 17742 | 10095 | B 168 | SB 168 |

Alloy 600/600 H Designations

| EN | 2.4816 – NiCr15Fe |

| ISO | NiCr15Fe8 |

| UNS | N0660 |

| AFNOR | NC15Fe |

Alloy 600/600 H Chemical Composition

| Min | 6.0 | 14.0 | Bal.. | 0.05 | - | - | - | - | - | - | - |

| Max | 10.0 | 17.0 | Bal.. | 0.15 | 0.015 | 1.0 | 0.5 | 0.3 | 0.5 | 0.02 | 0.3 |

Alloy 600/600 H Physical Properties

| 8.5 g/cm3 at 20 ℃ (531 lb/ft3 at 68 ℉) | 1,370 - 1,425 ℃(2,500 - 2,600 ℉) | 1.005 (Maximum) |

| Specific Heat | 455/0.109 | 495/0.118 | 508/0.121 | 550/0.131 | 620/0.148 | 635/0.152 |

| Thermal Conductivity | 14.8/102.7 | 17.0/117.9 | 18.4/127.7 | 22.0/152.6 | 27.5/190.8 | 31.2/216.5 |

| Electrical Resistivity | 103 | 106 | 107 | 111 | 112 | 114 |

| Modulus Of Elasticity | 214/31.0 | 205/29.7 | 200/29.0 | 187/27.1 | 163/23.6 | 143/20.7 |

| Co-efficient of Thermal Expansion | -/- | 14.1/7.83 | 14.4/8.0 | 15.1/8.39 | 16.1/8.94 | 16.9/9.39 |

Alloy 600/600 H Mechanical Properties

| Yield Strength MPa/ksi |

200/29.9 | 165/23.9 | 155/22.5 | 145/21.0 |

| Tensile Strength MPa/ksi |

550/79.8 | 500/72.5 | 485/70.3 | 475/68.9 |

| Elongation % |

30 | - | - | - |

| Yield Strength MPa/ksi |

180/26.1 | 160/23.2 | 150/21.8 | 145/21.0 |

| Tensile Strength MPa/ksi |

500-700/72.5-102 | 460/66.7 | 445/64.5 | 435/63.1 |

| Elongation % |

35 | - | - | - |

Welding Alloy 600/600 H

Alloy 600 and Alloy 600 H can be welded using the customary and conventional arc techniques such as TIG

or MIG impulse technology. The material should be in its annealed condition for welding. A low heat input and fast heat

removal must be ensured. The maximum interpass temperature should be between 100 and 150 °C (212 and 302 °F).

Usually neither pre-heating nor a subsequent heat treatment is necessary.

The generally applicable safety recommendations, especially for avoiding dust and smoke exposure must be observed.

| For TIG and MIG welding, a welding filler of the type: |

|---|

|