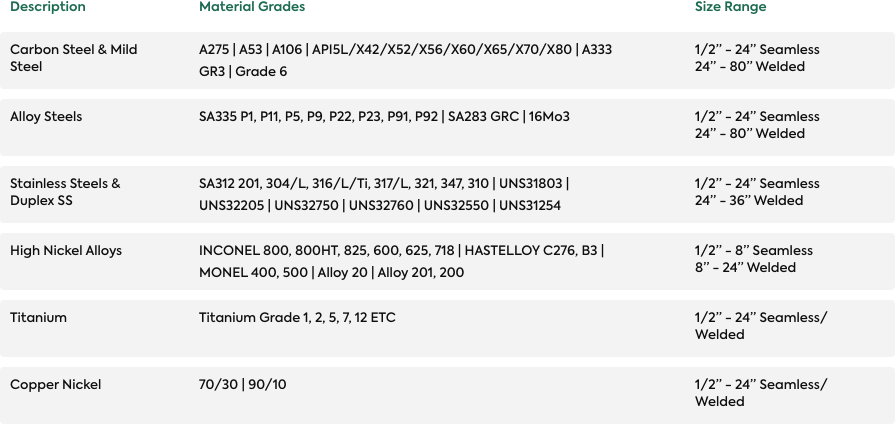

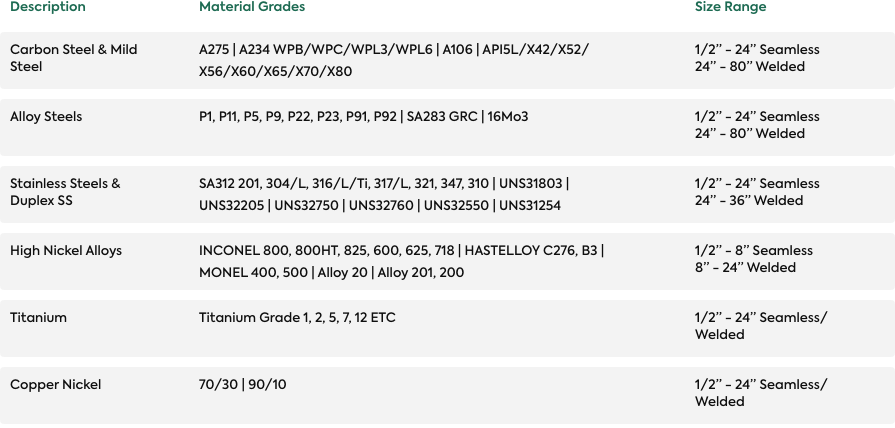

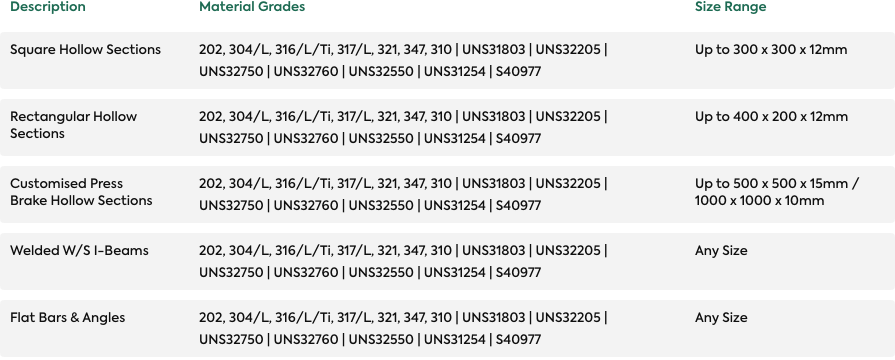

Forms

Alloy 625 Applications

The soft annealed version of Alloy 625 (grade 1) is used in the oil and gas industry, the chemical process industry, marine engineering and environmental engineering. Typical applications include:

- Equipment for the production of super phosphoric acid

- Plants for the treatment of radioactive waste

- Production pipe systems and linings of risers in oil production

- Offshore industry and seawater exposed equipment

- Sea water piping in shipbuilding

- Stress corrosion cracking resistant compensators

- Furnace linings

The solution annealed variant of Alloy 625 (grade 2) is used for high temperature applications up to 1,000 °C (1,832 °F), acc. to ASME Code for Pressure Vessels. Typical applications include:

- Flaring systems in refineries and offshore platforms

- Recuperators and compensators for hot exhaust gases

FM 625 is used as a matching filler metal for corrosion-resistant coatings of less resistant steels (overlay welding). Typical applications include:

- Components in the oil and gas extraction

- Superheater tubes in waste incineration plants

Alloy 625 is also approved by ASME in both the grade 1 and grade 2 conditions for sections I, III, VIII and XII at temperatures defined in ASME Section IID (temperature limits vary by construction code).

| Alloy 625 in the soft annealed condition (grade 1) is characterized by | Alloy 625 in the solution annealed condition (grade 2) is characterized by |

|---|---|

|

|

Alloy 625 Plate Standards

| Rod,Bar | 17744 17752 |

10228 | SB 446 | B 446 B 564 E 112 |

| Sheet,Plate | 17744 17750 |

6208 9722 |

SB 443 | B 443 |

| Strip | 17744 | 2662 | SB 443 | B 443 |

| Wire | 17744 17753 |

1088-3 | - | - |

Alloy 625 Designations

| EN | 2.4856 - NiCr22Mo9Nb |

| ISO | NC22DNb |

| UNS | N06625 |

| AFNOR | NC22DNb |

Alloy 625 Chemical Composition

| Min | 58 | 21 | - | - | - | - | - | - | - | - | - | 8 | 3.2 |

| Max | 71 | 23 | 5 | 0.03 | 0.5 | 0.4 | 1 | 0.4 | 0.4 | 0.01 | 0.01 | 10 | 3.8 |

Alloy 625 Physical Properties

| 8.47 g/cm3 (0.306 lb/in3) | 1,290 - 1,350 ℃(2,354 - 2,462 ℉) | 1.003 (Maximum) |

| Specific Heat | -/- | 392/521 | 932/573 | 1,472/663 | 1,832/684 | 2,192/705 |

| Thermal Conductivity | -/- | 14.2/98.5 | 19.3/133.8 | 26.8/185.8 | 28.2/195.5 | -/- |

| Electrical Resistivity | 120 | 127 | 132 | 129 | 128 | - |

| Modulus Of Elasticity | 209/30.3 | 195/28.3 | 178/25.8 | 153/22.2 | -/- | -/- |

| Co-efficient of Thermal Expansion | -/- | 13.03/7.2 | 13.94/7.7 | 15.68/8.7 | 16.63/9.2 | -/- |

Alloy 625 Mechanical Properties

| Yield Strength MPa/ksi |

330/479 | 260/37.7 | 225/32.6 | 1,832/100 |

| Tensile Strength MPa/ksi |

730/105.9 | 645/93.5 | 570/82.7 | 120/17.4 |

| Elongation % |

35 | - | - | - |

Alloy 625 Inventory

| Alloy 625 Pipe | 0.5 in | 8 in |

| Alloy 625 Coil | 0.25 mm | 3.18 mm |

| Alloy 625 Welding Wire | 0.5 mm | 3.175 mm |

| Alloy 625 Sheet and Plate | 0.25 mm | 76.2 mm |

| Alloy 625 Round Bar | 12 mm | 260 mm |

| Alloy 625 Pipe Fittings | 0.5 in | 8 in |

| Alloy 625 Flanges | 0.5 in | 8 in |

Welding Alloy 625

Alloy 625 can be joined by all conventional welding processes. These include GTAW (TIG), TIG hot wire, plasma arc, GMAW (MIG/MAG) and MAG-Tandem, submerged arc welding and SMAW (MMA). For welding, Alloy 625 should be in the soft or solution annealed condition and be free from scale, grease and markings. Pulsed arc welding is the preferred technique. For the MAG process the use of a multi-component shielding gas (Ar + He + H2 + CO2) is recommended.

When welding roots, sufficient protection of the root needs to be ensured with pure argon (Ar 4.6) so that the welding seam is free of oxides after welding. Root backing is also recommended for the first intermediate pass following the initial root pass and in some cases even for the second pass, depending on the weld set-up.

Any discoloration/heat tint should be removed preferably by brushing with a stainless steel wire brush while the weld metal is still hot.

Filler metal

| The following filler material is recommended: Welding rods, welding wire and wire electrodes | Welding strip for joint and overlay welding/cladding |

|---|---|

|

|