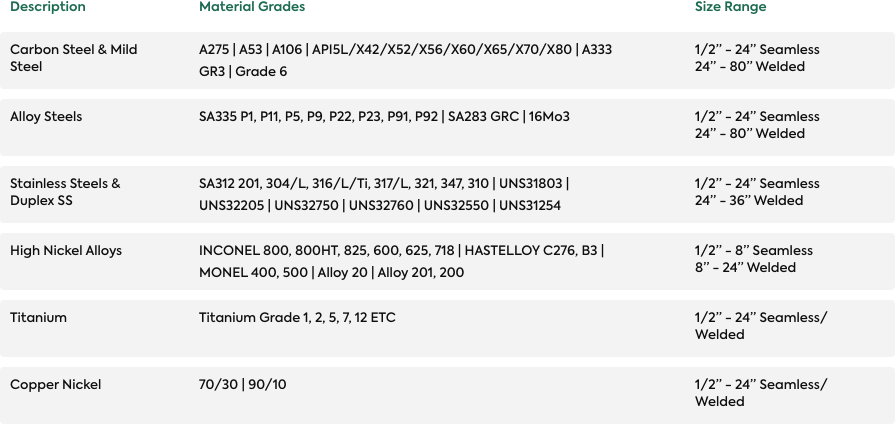

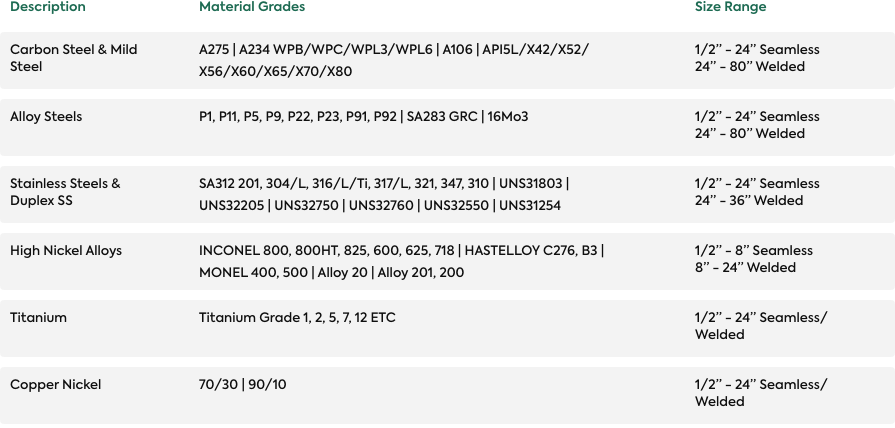

Forms

Alloy 926 Applications

Alloy 926 is an austenitic, special stainless steel that was developed on the basis of the many times proven Alloy 904 L (1.4539). Due to its 6.5 % higher molybdenum concentration, Alloy 926 has a generally

improved corrosion resistance and resistance against pitting corrosion and crevice corrosion compared to Alloy

904 L. This also has a positive effect on the resistance against stress corrosion that is induced by pitting corrosion.

Alloy 926 is characterized by:

- Very good resistance against chloride-induced stress corrosion.

- Increased resistance against stress corrosion in comparison to other austenitic stainless steels.

- Excellent general corrosion resistance when in contact with oxidizing and reducing media.

- Higher strength than Alloy 904 L (1.4539).

- low propensity to form inter-metallic phases.

- Approval for pressure vessels in the temperature range from -196 to 400 °C (-272.2 to 752 °F).

Typical applications for Alloy 926 are:

- Vaporizers, heat exchangers, tank housings, etc. in phosphorus acid production.

- Facilities and pipework in the use of diluted sulfuric and phosphorus acid, even if these are contaminated with

chlorides. - Distributor systems and coolers for sulfuric acid plants.

- Concentration and crystallization plants in salt extraction by vaporization .

- Fire extinguishing systems, sea water filtration, hydraulics and injection systems of off-shore engineering.

- Pump frames of oil extraction pumps

- Pump lines and couplings, wire lines in oil and gas extraction.

- Condenser pipes and pipework systems in power plants with heavily contaminated cooling water

- Parts for flue gas desulfurization that are exposed to modest corrosion strain

- Facilities and parts for the bleaching phase of the pulp industry

- Flexible pipes in the off-shore industry

- Tanks for storing and transport of aggressive chemical substances

Alloy 926 Plate Standards

| Bar | EN10088-3 | - | SB 649 | B 649 |

| Sheet | EN10088-2 EN10028-7 |

- | - | A 240 |

| Strip | EN 10028 EN 10088-2 |

- | SA 240 SB 625 |

A 240 B 625 |

| Wire | EN 10088-2 | - | - | - |

Alloy 926 Designations

| EN | 1.4529 X1 NiCrMoCuN25-20-7 |

| UNS | N08926 |

Alloy 926 Chemical Composition

| Min | - | - | 0.15 | 20.0 | 24.0 | - | - | 6.0 | 0.5 | - |

| Max | 0.02 | 0.010 | 0.25 | 21.0 | 26.0 | 1.0 | 0.5 | 7.0 | 1.5 | 0.03 |

Alloy 926 Physical Properties

| 8.1 g/cm3 (506 lb/ft3) | 1,320 - 1,390 ℃(2,408 - 2,534 ℉) | 1.001 |

| Specific Heat | 415/0.0991 | 435/0.104 | 470/0.112 | 495/0.118 | 510/0.122 |

| Thermal Conductivity | 12.0/6.93 | 12.9/7.45 | 14.4/8.32 | 16.5/9.53 | 18.5/10.7 |

| Electrical Resistivity | 96 | 99 | 104 | 108 | 112 |

| Modulus Of Elasticity | 193/28.0 | 186/27.0 | 179/26.0 | 173/25.1 | 168/24.0 |

| Co-efficient of Thermal Expansion | -/- | 15.0/8.33 | 15.7/8.72 | 16.1/8.94 | 16.4/9.11 |

Alloy 926 Mechanical Properties

| Yield Strength MPa/ksi |

300/43.5 | 190/27.6 | 160/23.2 | 105/15.2 |

Welding Alloy 926

As welding fillers, FM 59 (preferred) or FM 625 are recommended:

| Welding rods, welding wire and wire electrodes |

|---|

|