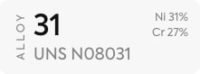

OIL & GAS

Our nickel based corrosion resistant alloy(s) (CRAs) are essential for providing long term resistance to corrosion for many components exposed to oil & gas production environments.

Excellent corrosion resistance, good mechanical properties, versatility and reliability make them the first choice in construction of process vessels, piping systems, pumps, and valves etc. designed for service in aqueous and high-temperature environments.

The selection of materials for sour environments is governed by a complex set of factors and, if not properly carried out, can lead to mistakes in application and misunderstanding about the performance of CRAs in a specific service environment. Good welding, fabrication and post-weld heat treatment practices are essential.

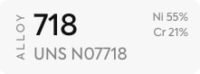

PETROCHEMICAL

Nickel alloys and other nickel-containing alloys are used extensively in the chemical, pharmaceutical and petrochemical industries. They possess corrosion resistance in aqueous, gaseous and high-temperature environments.

The chemical and petrochemical industries pose a unique set of challenges, including cryogenic applications, elevated temperatures, highly corrosive environments, high-pressure handling and the purity of final products.

Our nickel alloys have been widely embraced by the chemical and petrochemical industries. Their ability to withstand highly-corrosive substances over a wide range of temperatures, as well as their impressive mechanical characteristics help to drive high levels of demand.

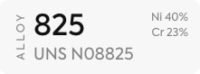

ENERGY & POWER

Our nickel based super alloys are widely popular for their outstanding resistance properties to corrosion and heat in addition of small thermal expansion features. These features are significant in industries that need components to retain stability and potential to prevent corrosion in the various temperature ranges.

Used in power production applications such as nuclear reactors, gas turbines, steam generators and compressors, they are subjected to the large levels of heat and extremely corrosive steam conditions.

Nickel alloy components are used in the power industry for their characteristics to prevent corrosion, deformation, fracturing and metal fatigue at the elevated temperatures. Our alloys have been developed with suitable workability, ductility and weldability to offer excellent cyclic oxidation at elevated temperatures. As these are made for service in the high temperature applications..

WATER TREATMENT

Nickel alloys offer a low-maintenance and durable design solution for water and wastewater installations. Characterized by its corrosion resistance and withstand erosive environments seen in wastewater application. The material convinces with its flexibility and is versatile to work with.

The use of nickel alloys in water technology guarantees good water quality and low maintenance. Successful desalination of water requires corrosion resistant material that withstands the aggressive seawater atmosphere. High performance stainless steels (including duplex) are an excellent choice.

Small and robust units allow contaminated groundwater and surface water to be processed and is ideal for hygienically demanding applications that are subject to frequent cleaning cycles.